PRODUCT FINDER

HIGHLIGHTED MARKETS

FEATURED BRANDS

SERVICES & SUPPORT

Everything you need to take your equipment to the next level: Upgrade kits, spare parts, refurbished equipment, and more.

FINANCING

Let us handle your equipment financing. We are always bank-competitive and often provide more favorable overall terms.

Protein Spotlight

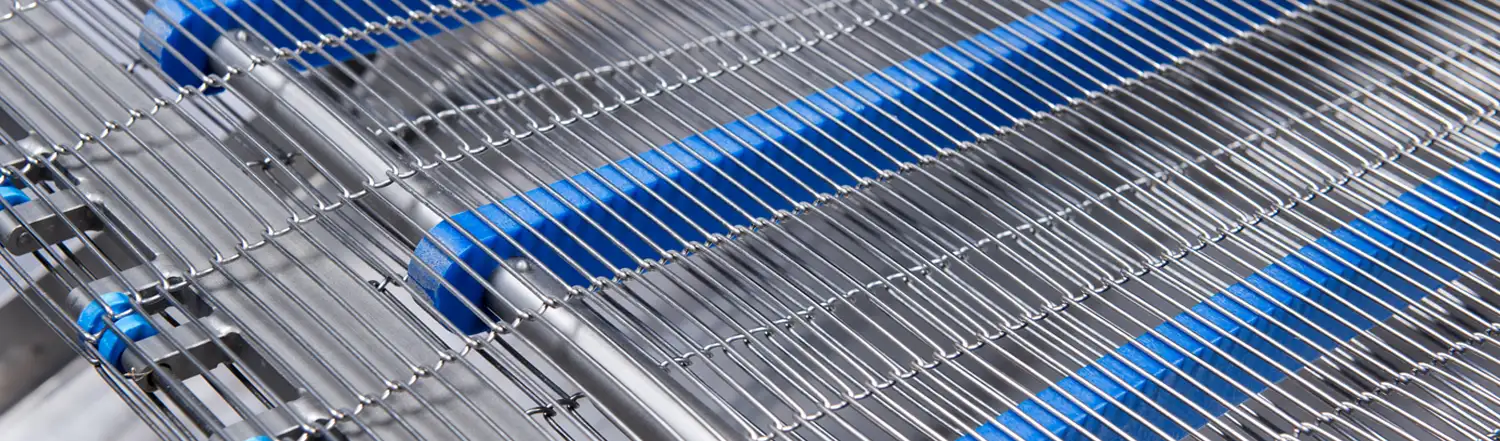

Thickness matters! JBT alco´s advanced flattening machines are designed to flatten various meat and poultry products with precision and efficiency.

Diversified Food & Health Spotlight

Extend shelf life without chemicals, additives or heat. HPP, a cold pasteurization technique, is extremely effective. Find an HPP tolling center near you.

Upcoming Events

Don´t miss the chance to talk to our food processing & packaging experts and explore our latest innovations and equipment at an upcoming show.